Last Updated on: 11th September 2025, 12:13 pm

Screen printing can be a tedious task and requires a bit of manual effort. However, if you are a medium or large-scale screen printer, you cannot afford to have a manual process under your roof.

Looking forward to the demand for automatic screen printers, I have come up with a list of the top 10 automatic screen printing machines.

However, for the interest of my readers, I came out of my comfort zone to meet all the screen printing experts who have more than five years of experience in this industry. Therefore, they recommended me a few.

Moreover, I also consulted the respective screen printing companies and tried to dig out all sorts of information that may be helpful to you. More to say, out of my research and hard work I have come with the list of top 10 screen printers.

I hope you like my work.

Moreover, I would welcome and appreciate your comments based on the information stated below.

What are the Top 10 Automatic Screen Printing Machines? There are a number of automatic screen printing machines available but I have boiled it down to just the best 10 that you should get if you are serious about your screen printing business.

- M&R Gauntlet 4 Automatic Screen Printing Press

- Anatol VOLT L Automatic Screen Printing Press

- M&R Cobra Automatic Screen Printing Machine

- ROQ OVAL EVOLUTION Automatic Screen Printing Press

- Systematic Automation Screen Printing Machine

- Workhorse SABRE 12/14

- Riley Hopkins 360 8 Color 6(Manual)

- MHM Synchroprint 5000

- ROQprint ECO P18 XL

- Tas Hawk HX20

These machines are designed to handle high volumes of orders, complicated prints, and faster output. Moreover, screen printing software is compatible with these machines. From design creation, color separation, artwork approval, and production management, making it seamless to feed jobs into these machines, auto-track and monitor all pending/in-progress/completed jobs.”

Top 10 Automatic Screen Printing Machines:

You need to automate this process. Therefore, you need a way to print thousands of screen-printed machines at a time.

So, here I have come up with a list of the top 10 automatic screen printing machines you need to run your print business like a pro.

1.M&R Gauntlet 4 Automatic Screen Printing Machine

- High-production oval automatic screen printing press: M&R’s Gauntlet 4 is a modular system with 16/14, 18/16, or 20/18 station/color configurations, expandable for larger setups. It can handle up to 20 stations and 18 colors for multi-color jobs.

- All stations can support printheads, with the option to leave some open for flexibility. Supports maximum image areas of 51 x 51 cm (20" x 20") or 51 x 71 cm (20" x 28"), and up to 117 x 71 cm (46" x 28") with alternating printheads.

- Equipped with a large 15.6" machine-mounted control panel featuring a digital touchscreen that displays information and commands in multiple languages.

- Features a precise pallet leveling system with tool-free off-contact settings and 1–4 print stroke capability.

- Backed by a two-year or 2,000,000-cycle limited warranty

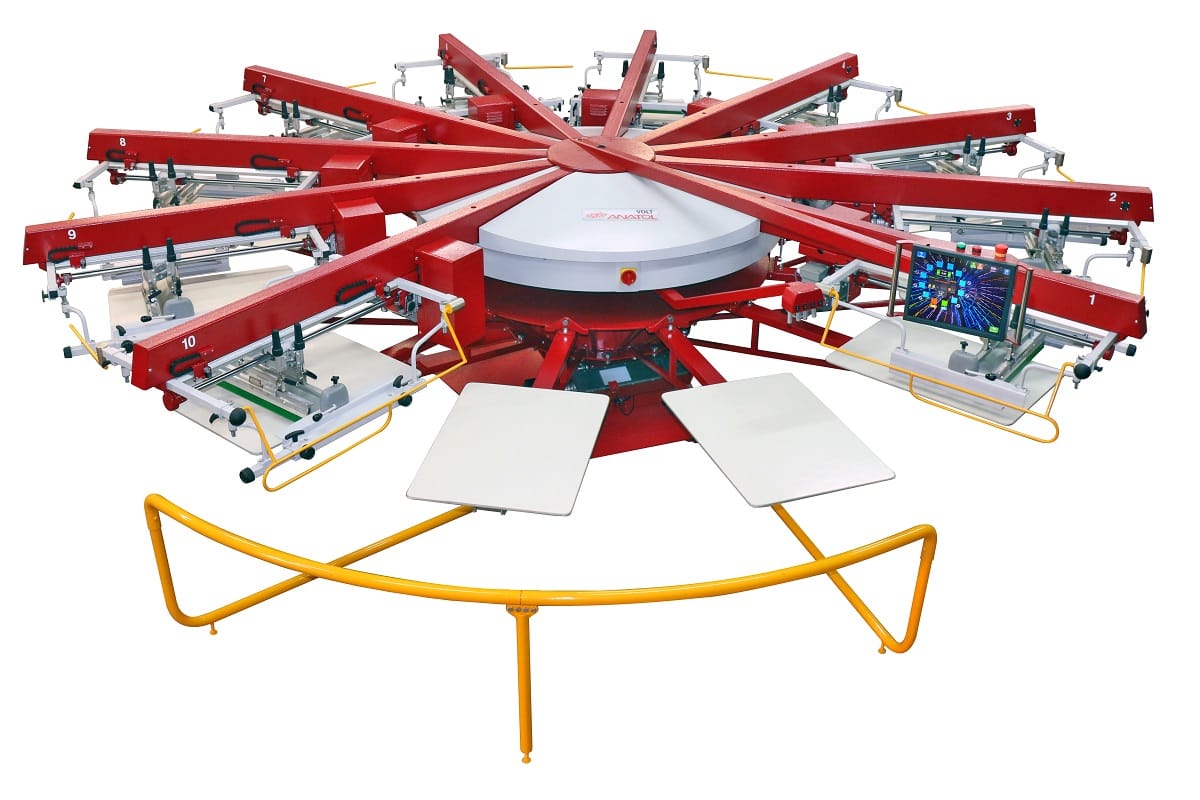

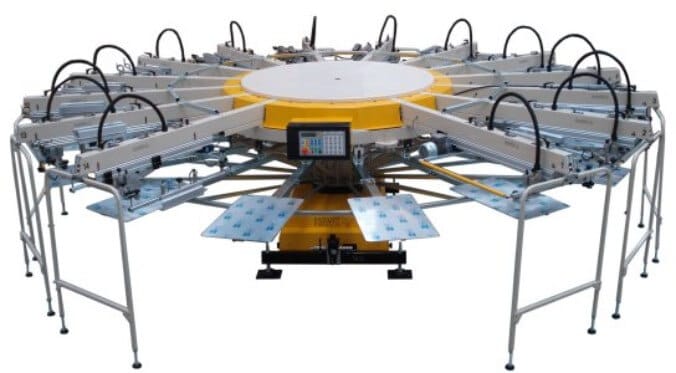

2.Anatol VOLT L Automatic Screen Printing Machine

- Available in setups ranging from 6 stations/4 colors to 20 stations/18 colors. It supports maximum print areas from 15” x 16” up to 20” x 28”.

- Equipped with a servo indexer that rotates pallets smoothly and quietly, even at high speeds, ensuring precise control and reducing vibration for consistent prints.

- Offers multiple indexing options: clockwise, counter-clockwise, full or half indexing, plus a step-back mode for print-flash-print jobs. Pallet positioning is accurate to within +/- 0.001”.

- Features a servo-driven pallet lift and lower system, eliminating manual adjustments. This allows digital off-contact adjustment directly from the touchscreen.

- Provides a 0–3/8” off-contact range adjustable in 0.01” increments, giving printers exact control for different job requirements.

3.M&R Cobra Automatic Screen Printing Machine

- The automatic screen printing press available in multiple configurations, from 10/8 up to 14/12 stations/colors.

- Supports a maximum image area of 16" x 18" (41 x 46 cm) for Cobra E 1618 models and 20" x 20" (51 x 51 cm) for Cobra E 2020 models.

- Designed with a robust flat indexing system for smooth, quiet operation.

- Equipped with Quick-Flip™ front frame holders with pneumatic locking and a slimline pallet-leveling adjustment system for easier setup.

- Features precision front and rear micro-registration controls along with simple on-head off-contact controls.

- Printheads use a membrane switch-based control system for quicker setup and consistent repeatability.

- Comes with a built-in Maintenance Minder™ system that provides alerts with photos and descriptions when scheduled maintenance is due.

- Includes a 7.5" high-resolution touchscreen interface with icon-based logic, multi-language setup guides, and built-in tutorials for simplified training

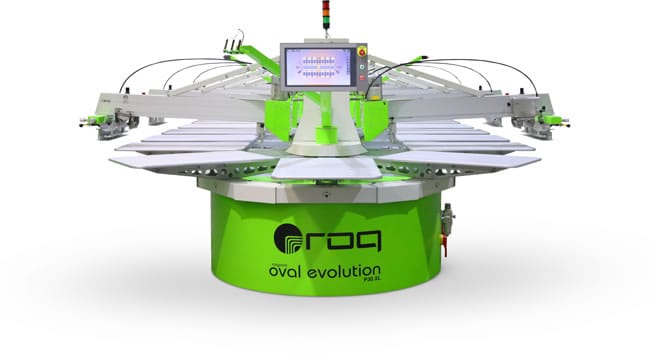

4.ROQ OVAL EVOLUTION Automatic Screen Printing Press

- The ROQ Oval Evolution is a high-production automatic press capable of printing up to 950 garments per hour.

- Supports large print areas ranging from 19.7" x 27.6" (500 x 700 mm) up to 43.4" x 63.0" (1100 x 1600 mm).

- Accommodates up to 56 extra-wide pallets, allowing for oversized and all-over prints.

- Maintains precise registration accuracy of ± 0.1 in, ensuring consistent results on complex multi-color jobs.

- Integrates easily with flashes, as well as ROQflock and ROQfoil accessories for expanded creative options.

- Features include lightweight honeycomb aluminum pallets, 15" color touchscreen control console, command panels on each print head, safety bars, and pneumatic print head elevation for easier screen cleaning.

- Uses an AC servo-motor indexing system for smooth and quiet operation.

- Offers a rear command station to manage double production.

- Optional upgrades include laser markers, flash cure units, and built-in power/control connections for accessories.

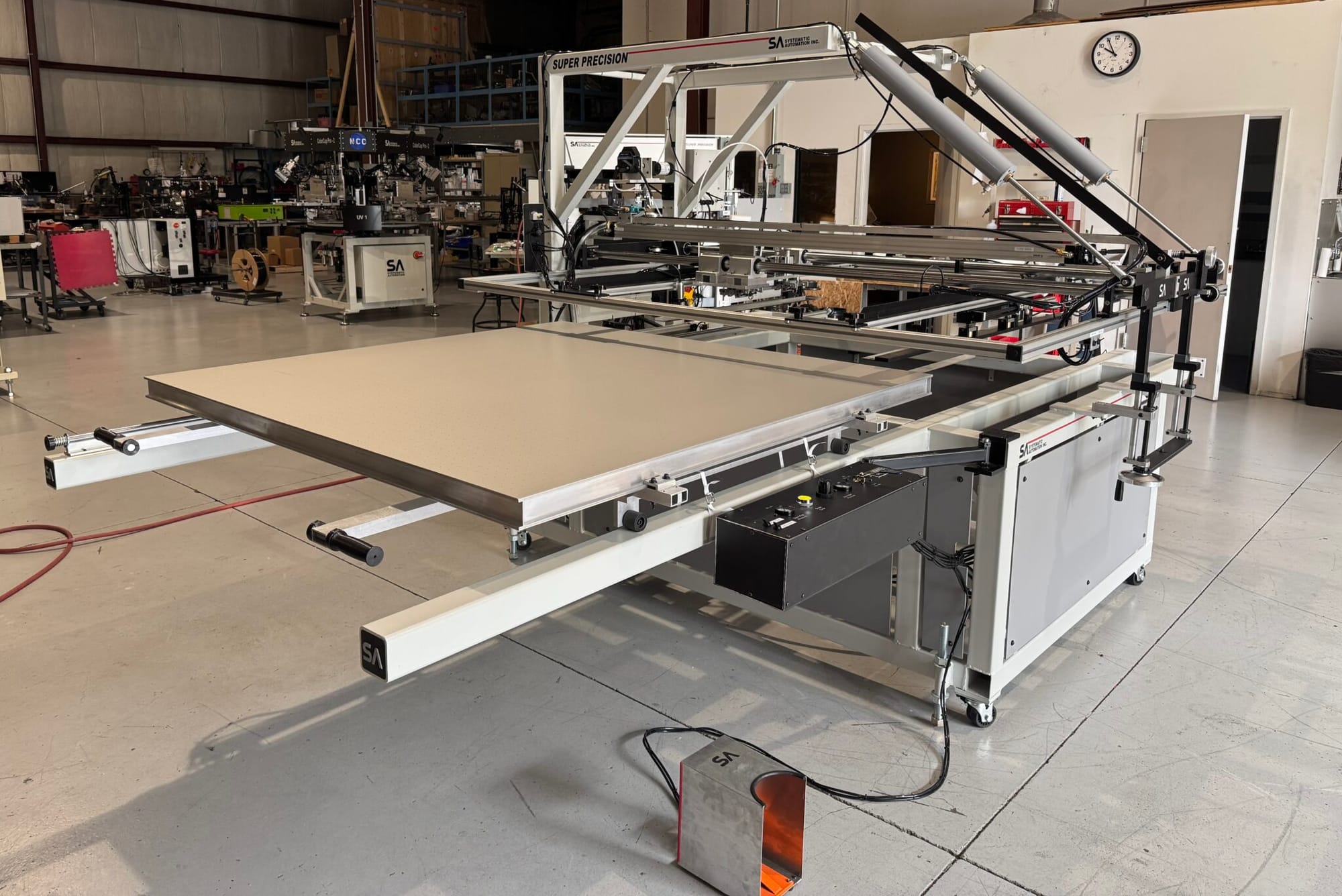

5.Systematic Automation Screen Printing Machine

- The ST-60 is a flatbed screen printing system designed for industrial-scale applications, with a large 60" x 60" print area.

- Uses a fully pneumatic control panel with access to single-cycle operation, squeegee pressure, vacuum toggle, carriage movement, and air control, with real-time pressure monitoring.

- Equipped with pneumatic front and rear clamps, adjustable forced peel, and a hinged rear holder for easy access to squeegee and flood bar without losing registration.

- Motion system relies on linear bearings rated for over 300 million cycles, with overload protection for reliability.

- Includes X, Y, and angular micro-adjustments for precise screen alignment on detailed jobs.

- Designed with casters and leveling pads for easy relocation and setup, with options for custom sizes.

6.Workhorse SABRE 12/14

- The Workhorse Sabre 12/14 is an automatic screen printing press with a standard print area of 20" x 28" and an overall diameter of 18' (5.5 m).

- Equipped with front and rear micro-registration for precise alignment during setup.

- Features independent print and flood speed controls with pneumatic screen clamps at the front and rear.

- On-head print controls allow direct operation, with an advanced chopper system that improves stroke length for larger image areas.

- Default up-state keeps the squeegee and floodbar lifted off the screen, simplifying setup and tear-down.

- Supports multiple print strokes (1–9) with the option for multi-print in the up position.

- Includes onboard self-diagnostics for system monitoring.

- Pivoting control panel with touchscreen display provides access to real-time production data and easy adjustments.

- Countdown program alerts operators when the set index count has been reached.

- Independent print-start/finish settings automatically engage and stop printheads at the beginning and end of runs.

7.Riley Hopkins 360 8 Color 6(Manual)

- The Riley Hopkins 360 is a manual screen printing press designed for precision, versatility, and long-term reliability.

- Offers a choice between side clamps or back clamps, giving flexibility for different screen setups.

- Equipped with micro-locking levers, machined tilting blocks, spring-loaded XY micro adjustments, and a Z micro adjustment for accurate alignment.

- Provides machined off-contact adjustments and a tilt adjustment knob for fine-tuned control over prints.

- Uses a 4-point roller gate system to stabilize the printhead and guide screens securely into place.

- Built on an adjustable CNC-constructed base with up to 3 inches of height adjustment, reinforced heads/arms, and heavy-duty leveling feet for stability.

- Registration gate and contact system are made from aircraft-grade aluminum, reducing flex and ensuring durability.

- Includes classic Riley-style arms with a platen locating ruler and tubular print station for easier setups.

- Flexible clamping options: side clamps with aluminum crossbar or back clamps with locking levers.

- Backed by a limited lifetime warranty covering all non-wearable parts and components.

8.MHM Synchroprint 5000

- It is a high-production oval screen printing press available. M&R’s Gauntlet® 4 is a modular system with 16/14, 18/16, or 20/18 station/color configurations, expandable for larger setups. In other words, it handles up to 20 stations and 18 colors for multi-color jobs.

- All stations can support printheads, and any can be left open for flexibility. In addition, it supports maximum image areas of 51 x 51 cm (20" x 20") or 51 x 71 cm (20" x 28"), and up to 117 x 71 cm (46" x 28") with alternating printheads.

- A large 15.6" machine-mounted control panel with digital touchscreen displays information and commands in multiple languages.

- Precise pallet leveling system with tool-free off-contact settings and 1-4 print stroke capability.

- Additionally, it comes with a two-year or 2,000,000-cycle limited warranty.

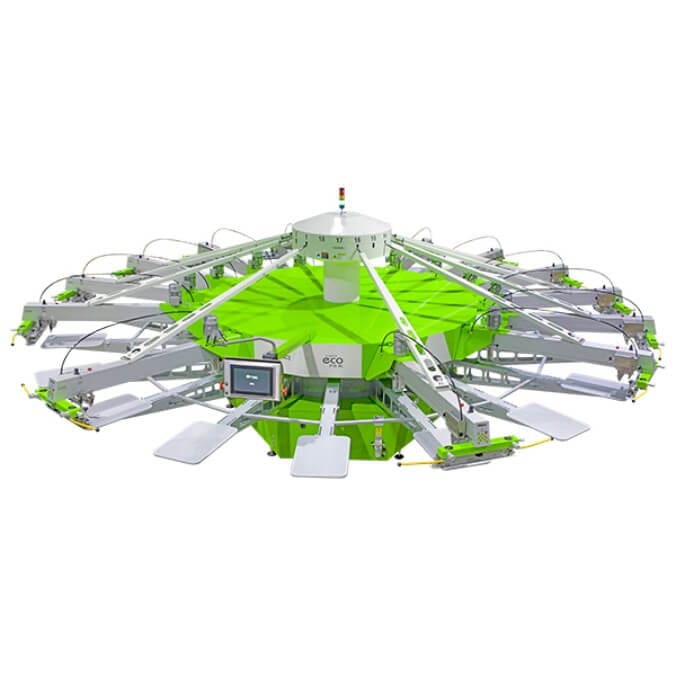

9. ROQprint ECO P18 XL

- The ROQprint Eco incorporates ROQ’s latest technological innovations. It ranges from a minimum of 12 pallets to a maximum of 20 pallets and from a minimum of 1 color up to 18 colors.

- Especially, this is suitable for the most demanding of printers as it is efficient and is capable of output a maximum of 1400 pieces per hour.

- It has a central control panel with a Polychromatic 10 inch LCD touch screen to give you complete control over the screen printing machine.

- It has a maximum printing area of 1000x1100 mm and best for suits of sizes L, XL+, 2XL, and 3XL.

- This is particularly efficient in printing with water-based inks and the printer can manage the time that the screen is in contact with the hot pallets.

- Less time in contact means less evaporation of the inks, which leads to fewer stops during the printing of the job.

10.Tas Hawk HX20

- The Screen printing machine is available with 20 print stations/18 colors having a screen size of 23 x 31 inches

- It is installed with a 17” touchscreen control panel and individual membrane control panels to give you complete control of each print station.

- The standard size of the palette- 18 x 22 inches

- Moreover, the screen printing machine comes with 3 years warranty.

Related Questions

What Do I Need to Start a Home Screen Printing Business?

Your home screen printing supplies should include:- Screen and frame (~$15)

- Photo emulsion and sensitizer (~$20).

- A 250-watt bulb (~$5)

- Latex gloves

- A pitch-black room

- A t-shirt

- Squeegee (~$15)

- Silk Screen Fabric Ink (~$5)

- Small piece of cardboard

Recommended books: A Practical Guide to Starting Your Own T-Shirt Business

What is the Cost of Starting a Home Screen Printing Business?

It is relatively cheaper compared to starting a DTG printing business. A basic printer would cost nearly $10,000; supplies would cost nearly $5,000; setting up a website will cost nearly $500; and other advertising would cost nearly $5,000; so, you can expect to spend nearly $21,000 initially to starting a basic screen printing business.What is the Cost of Each Screen Print?

A 1 color print on a cotton t-shirt would range from $5 to $9 per t-shirt. For a 6 color print for 72 shirts, it would take less than 30 minutes and would cost nearly $600 in total or nearly $8 per t-shirt.

What are the tools needed for screen printing?

The minimum set of tools you would need includes screens, squeezes, emulsion, fillers, clamp, plastic glass, acetate, lightbox, masking tape, mesh sheets, gloves, aprons, stencils, etc.